Resco® Resin Bound Binder Kit

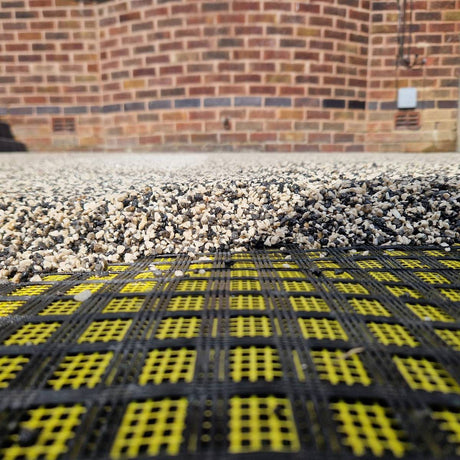

Our resin bound binders are products that offers exceptional quality, durability, and versatility. It is designed to provide a long-lasting, high-quality surface that is perfect for a wide range of residential and commercial applications. By using this product with decorative dried aggregates, you can create stunning resin-bound surfaces that are not only beautiful but also built to last.

All of our resin bound binders:

We offer four types of resin binders, each tailored to specific project needs and environmental conditions:

-

UVR Resin Binder 7.5kg:

Ideal for outdoor applications, this binder offers superior UV stability, ensuring long-lasting colour retention and surface integrity.

Learn more

-

UVR Resin Binder 7kg:

This binder provides excellent UV resistance and is perfect for projects requiring a slightly lighter resin option without compromising quality.

Learn more

-

UVR Moisture Tolerant Binder:

Specially formulated to tolerate moisture during application, this binder is for environments where controlling moisture is a challenge.

Learn more

-

Non-UV Resin Binder 6.5kg:

Best suited for indoor or shaded applications, this cost-effective option still delivers robust performance and durability.

Learn more

RESCO - Ultimate UVR Resin Moisture Tolerant (MT) - Resin Bound Binder - 7.25KG

a groundbreaking innovation in the world of resin-bound surfaces. This state-of-the-art, solvent-free, two-part aliphatic polyurethane resin binder is not only UV stable but now boasts enhanced moisture tolerance, making it an unparalleled choice for both residential and commercial applications under various weather conditions.

The RESCO - Ultimate UVR Resin MT represents the zenith of resin-bound technology, meticulously designed for use with decorative dried aggregates to create surfaces that are not only visually stunning but also exceptionally durable and UV-resistant. Manufactured in the UK to the stringent ISO:9001 standards from superior quality raw materials, this product exemplifies the highest levels of quality and consistency. The high-grade polyurethane used in its formulation ensures that it is the ideal system for crafting resilient resin-bound surfaces that stand the test of time.

This versatile binder is perfect for a myriad of applications, including driveways, paths, porches, patios, walkways, and carparks. Its robustness, aesthetic appeal, and performance make it a favoured choice for projects where excellence is a prerequisite. Moreover, the RESCO - Ultimate UVR Resin MT's UV stability and moisture tolerance mean that surfaces maintain their colour and integrity even in outdoor settings prone to sunlight exposure and moisture.

In addition to these outstanding features, the RESCO - Ultimate UVR Resin MT comes with a 15-year guarantee that the colour of the polyurethane resin will remain unchanged, underscoring our confidence in this product's longevity and quality (conditions apply, please contact us for details).

Recommended Mix Design: For each 7.5kg kit of RESCO - Ultimate UVR Resin MT, it is recommended to mix with:

- 75 kgs of 2-5mm dried aggregate

- 25 kgs of 1-3mm dried aggregate

- 6.25 kgs of binding quartz, Totalling 106.25 kgs, with the resin constituting 7.06% of the mix. This balanced composition ensures an optimal texture and strength for your surfaces.

View Aggregate Blends

Coverage Rates:

- Pedestrian Traffic: 4.05m2 at 15mm thickness on average.

- Vehicle Traffic: 3.55m2 at 18mm thickness on average. (Note: Aggregate density variations may affect these rates; ordering 10% extra is recommended to account for wastage.)

Additional Information:

- Complies with SUD's regulations for sustainable drainage

- Exhibits excellent moisture tolerance for enhanced durability

- Suitable for heavy foot traffic within 24 hours of application

- Retains its colour over time due to UV stability